The working principle of the automotive turbocharger bypass valve

2022-11-04 12:14First, the working principle of the bypass valve turbocharger

At high speed and high load, the bypass valve of the turbochargerS410 169060 136-7619 0R7142 TURBO

accessories is opened, and part of the exhaust gas directly enters the exhaust pipe through

the bypass valve, releasing part of the exhaust gas, and the turbine speed decreases, so as to control

the pressure of the boost. There are two control methods of bypass valve turbochargers, one is

mechanical supercharging, which is usually used in truck diesel engines; The other is electronic

control, which is usually used in cars.

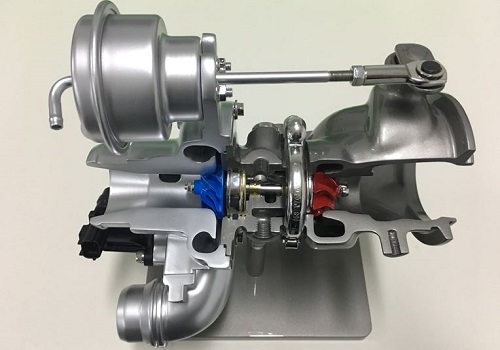

Second, the structure and working principle of mechanical control bypass valve

Mechanical control bypass valve is mainly composed of control air chamber, tie rod, solenoid valves,

etc. Pressurized gas on the left side of the diaphragm in a bypass valve actuator. When the engine

runs at low speed, the compressor outlet pressure is low, the bypass valve is closed under the action

of the return spring, and the exhaust gas discharged by the engine all passes through the turbine

end of the supercharger, thereby increasing the speed of the turbine, which can generate a large

intake boost pressure, increase the intake air, and improve the low-speed performance of the

engine.

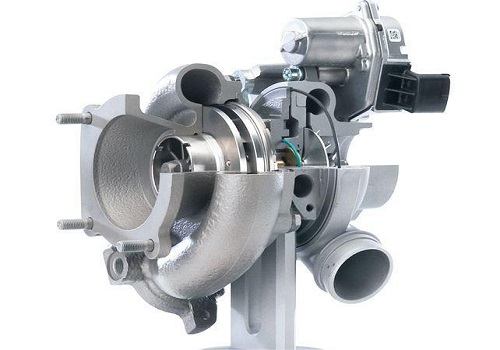

Third, the structure and working principle of electronically controlled bypass valve

The opening and closing of the exhaust bypass valve is controlled by a pressurized pressure control

solenoid valve controlled by the ECU of the electronic control unit. The ECU of the electronic control

unit monitors the working conditions of the engine, compares with the internal preset parameters,

and controls the opening time of the solenoid valve accordingly, so as to change the opening of the

exhaust bypass valve, control the exhaust bypass flux, and accurately adjust the pressurization

pressure.