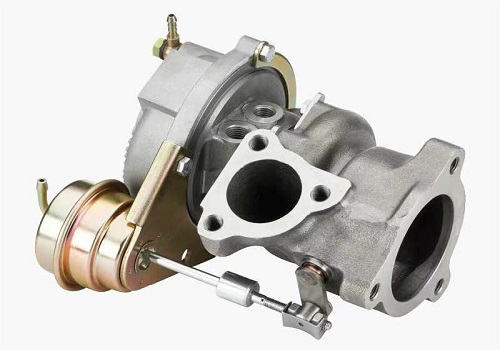

The working principle and classification of exhaust gas turbocharger

2022-10-31 08:59Exhaust gas turbocharger working principle: exhaust gas from the engine exhaust manifold

is high temperature and high pressure, with a certain amount of energy. In naturally

aspirated engines, this energy is often wasted as the exhaust gas is emitted. And the

exhaust gas turbocharger power source is mainly these exhaust gases. The turbine impeller

and compressor impeller are rigidly connected through the supercharger shaft, which is

called the supercharger rotor. The rotor of the supercharger is fixed in the supercharger

by floating bearing.

When the engine is working, the exhaust gas impinges the turbine impeller at a certain

Angle at a high speed, so that the supercharger rotor rotates at a high speed. The high

speed rotation of the compressor impeller makes the air pressure in the intake manifold

of the engine rise, so as to achieve the pressurization effect. In this way, during the intake

process, the air will be subjected to a greater pressure, so that more and denser air into

the cylinder. In this way, the fuel can be burned more fully and the performance of the

engine can be improved.

Classification of exhaust gas turbochargers: according to the different turbines used,

exhaust gas turbochargers are divided into runoff and axial flow two kinds. Runoff

turbocharger adopts runoff turbine and centrifugal compressor, small flow, suitable for

medium and small power internal combustion engine; Axial flow turbocharger adopts

axial flow turbine and centrifugal compressor, with large flow, suitable for large diesel

engines.