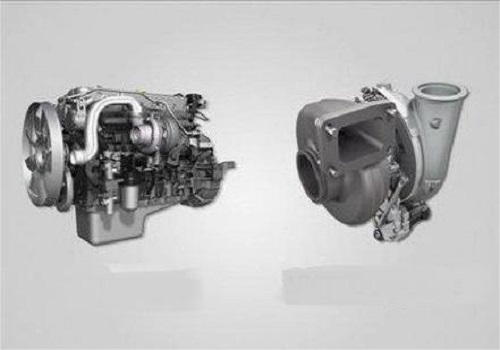

Vacuumschmelze launches new alloy turbochargers

2022-06-29 10:48At present, the automotive industry is increasing the emission reduction requirements for

internal combustion engine vehicles.Materials specialist Vacuumschmelze GmbH (VAC) is

contributing to this goal with its new VACOMAX 262 TP permanent magnet. The samarium

cobalt alloy helps designers shrink electric turbochargers for internal combustion engines

and high-speed permanent magnet motors for hydrogen fuel cell air compressors.

Air compressors and electric turbochargers can operate at speeds of more than 100,000

RPM, which, coupled with low delay requirements, result in application temperatures of

around 200°C. The VACOMAX 262 TP not only provides excellent high temperature

performance, but also has a higher energy density than all current SmCo magnets,

enabling a very compact system size.

Due to VAC's unique high yield single-piece stamping technology, the VACOMAX 262

TP can be used for high-volume requirements in the automotive industry. In many

applications, high speeds can cause mechanical stress in the rotor. The remedy is to

protect the brittle material with metal or carbon fiber bandages. Bundling and balancing

rotor assemblies, as well as a complete range of in-house skills from material develop-

ment to rotor assembly, make VAC more competitive.

"Using an electric turbocharger to control the ratio of fuel to air during combustion

makes the engine cleaner," says Alex Barcza, permanent Magnet product manager.

In addition, eliminating turbine lag can lead to a more dynamic driving experience,

which makes electric turbocharging an attractive accessory for the automotive industry.

VAC has the best magnet grades for each application. We are excited to contribute

to a cleaner environment by helping to build cleaner engines."