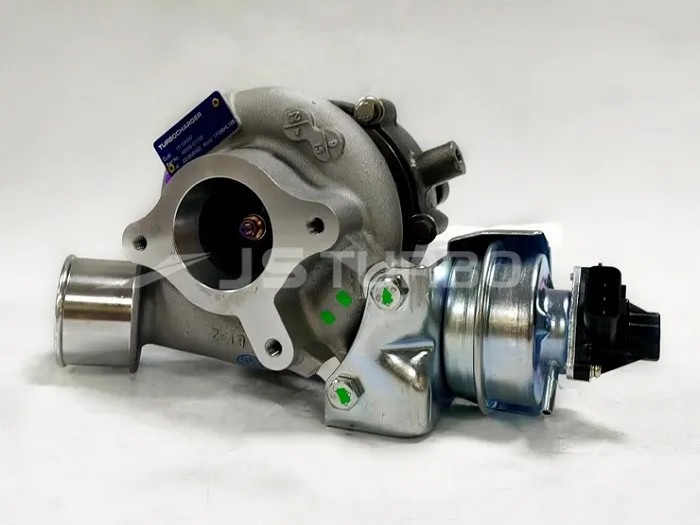

Inspection and replacement judgment of turbocharger components

2023-03-20 14:041. Supercharger floating bearing

The bearings of turbochargers usually adopt floating bearings or rolling bearings. High-speed turbochargers use high-reliability floating bearings. There is a certain gap between the floating bearing and the rotor journal and the bearing seat of the middle shell. During the operation of the turbocharger, the rotor shaft and the floating bearing are all floating in the lubricating oil, and there is no mechanical friction between them. The lubrication between the rotor shaft and the bearing of the booster adopts pressure lubrication. The lubricating oil comes from the main oil passage of the engine, and after being filtered through a fine filter, it enters the middle casing of the supercharger.

If the engine oil is dirty or deteriorated during use, the floating bearing is not easy to form an oil film, and the bearing is easily scratched in semi-dry friction, and even the bearing is deformed or blue due to overheating. If it is scratched, deformed or blue after disassembly, it needs to be replaced. If carbon deposits are found in the floating bearing in the middle of the turbocharger during the inspection, the inlet and outlet of the lubricating oil of the turbocharger should be dredged; the oil filter element should be replaced, and standard oil should be filled.

2. Thrust bearing plate

When the turbocharger is working, if the oil supply is sufficient, the thrust bearing plate generally does not wear out, but if the oil is too dirty or deteriorated, it is easy to block the oil inlet hole, resulting in semi-dry friction, wear, and deformation. Case replacement.

3. Overhaul of the air compressor housing

If the inlet of the pressurized surface of the air compressor casing has slight scratches, you can use fine abrasive cloth to smooth out the small burrs and nicks on the compressor casing; if there are deep scratches on the inlet of the pressurized surface of the air compressor casing, you cannot continue to use it . If the compressor housing is cracked or deformed, it should be discarded.

4. Overhaul of turbine housing

The role of the turbine casing is to collect the air flowing from the diffuser and direct it to the compressor outlet. The air continues to decelerate and pressurize in the volute, completing the process of transforming from kinetic energy to pressure energy.

Visually check whether the turbine casing is in contact with the impeller; check for cracks at the mounting flange and V-shaped hoop. Check whether there are cracks at the inlet end of the turbine casing, whether there is deformation and burning at the inlet and outlet of the turbine casing, and replace it with a new one if there are cracks, deformation, burning, or severe corrosion. Under normal circumstances, the turbine and bearing seals should be replaced after the tractor farmland operation or transportation operation has a mileage of 50,000 to 60,000 km.

5. Overhaul of the bearing shell

Check the cracks of the bearing shell at the oil inlet and oil return joints; measure the inner diameter of the bearing shell hole; measure the length of the bearing shell at 4 equidistant positions from the outlet of the air compressor shell to the outlet of the turbine shell; if the measurement results show that the bearing shell has If there is any distortion, the bearing shell should be discarded.